Tel: (301) 541-3662 (EMMA)

E-Mail: info@templeallen.com

EMMA™ & SAM™ Videos

SAM™ Family |

SAM™ Tabletop Jitterbug Tool |

SAM™ & EMMA™ with DCC |

|

|

|

EMMA™ Belly Systems |

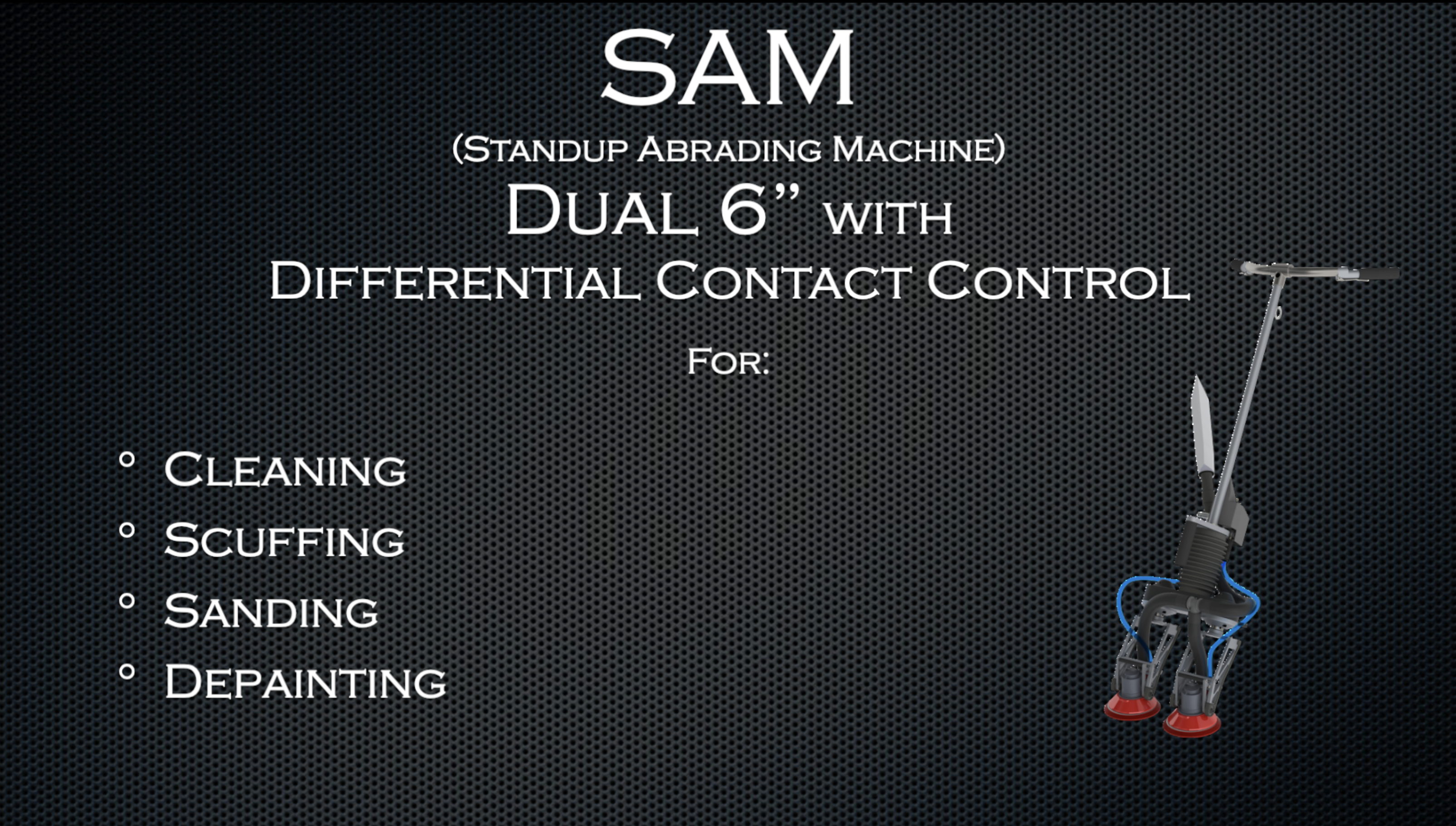

SAM™ Dual 6" with DCC |

|

|

|

|

|

||

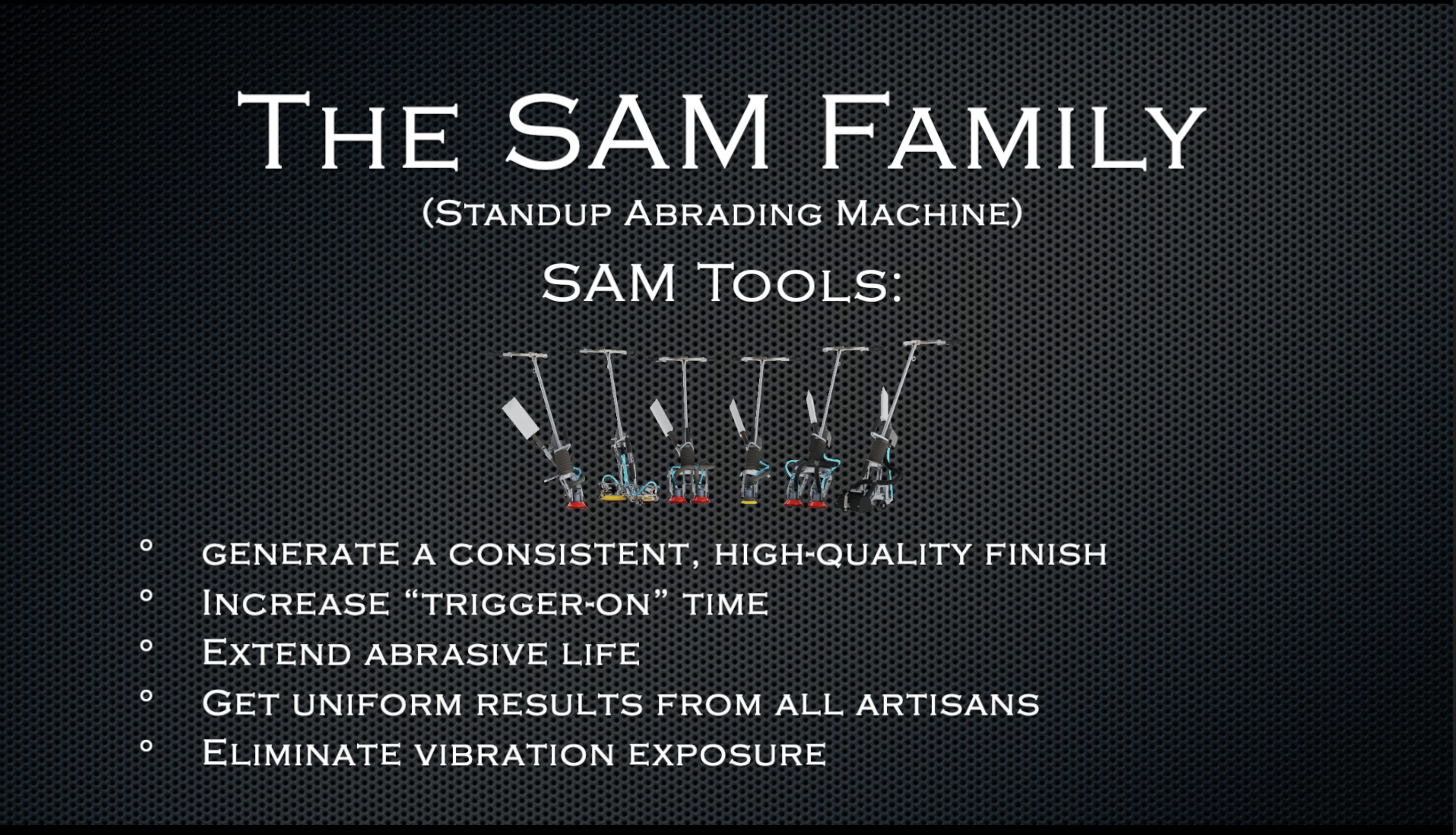

The first video introduces our SAM™ Family of Standup and Table Height Abrading Tools. SAM is designed to conduct a range of surface preparation tasks normally performed by artisans bending over or on their knees. SAM allows the artisan to stand comfortably and perform the same tasks while being protected from vibration, dust, and poor postures.

1] SAM™ Family

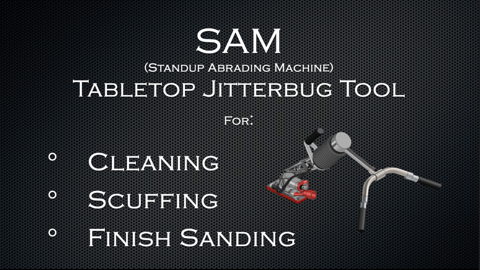

The second video shows our new SAM™ Tabletop Jitterbug Tool, which brings all the productivity and ergonomic advantages of our SAM tools to cleaning, scuffing, and sanding tasks performed on flight controls, rudders, rotor blades and other composite panels positioned at table height.

2] SAM™ Tabletop Jitterbug Tool

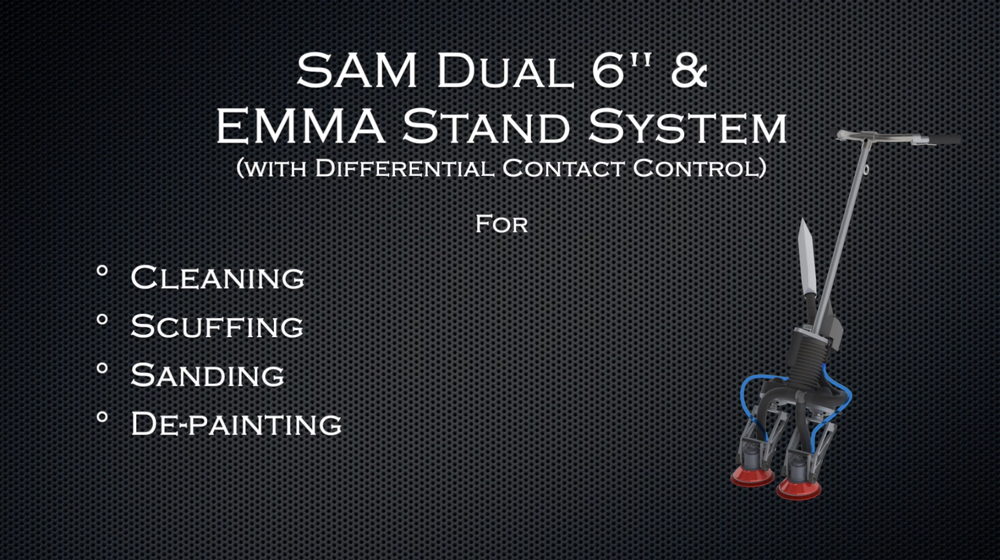

The third video shows our new SAM™ and EMMA™ solution for wing sanding for business aircraft, featuring our patent-pending Differential Contact Control™ - a productivity and quality enhancement over traditional tools.

3] SAM™ Dual 6" & EMMA Stand System, with Differential Contact Control™

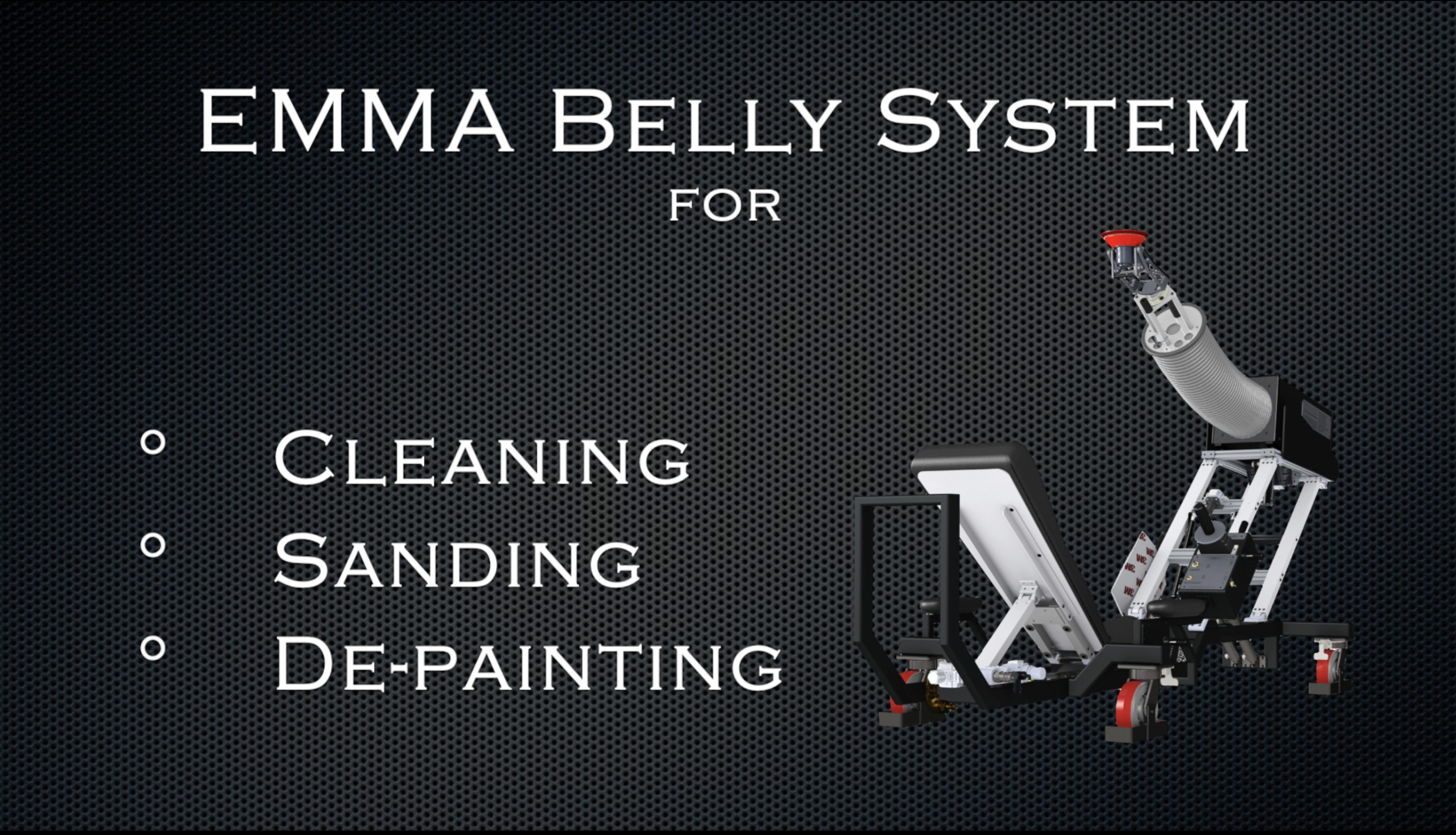

The fourth video shows our EMMA™ Belly System - the world's best way to perform overhead cleaning, sanding, and de-painting underneath the fuselage of commercial, business, and military aircraft. Belly Systems can also sand underneath wings of business and combat jets.

4] EMMA™ Belly System™

The fifth video shows our SAM™ Dual 6" with Differential Contact Control - featuring our patent-pending method for boosting sanding productivity by offering a controlled bias of the sanding pad on the surface. In practice, this enables artisans to achieve in two hours the same amount of surface preparation that normally requires a full shift.

5] SAM™ Dual 6" with Differential Contact Control™

Copyright © 2019 - All Rights Reserved - Temple Allen Industries